Description

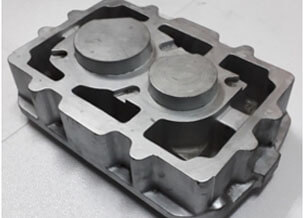

- ITTI’s Casting and Machining Division offers design and manufacture of precision components from multiple grades of Ferrous and Non-ferrous castings.

- We focused on specialized molding and manufacturing processes for geometrically critical parts with close tolerances.

- We offer one-stop shop for your casting requirements. We have the ability to manufacture and supply a range of Sand, Gravity, Investment, Steel and Pressure Die Cast components using vide range of metals.

- We have state-of-the-art machinery, highly skilled work force and ISO 9001 Quality Management System with full participation by the entire management team including the CEO. The facility is housed in a 25000 Square foot building in the city of Ahmedabad, in India’s most business-friendly State of Gujarat.

- Components ranging from 1 Kg to 1000 Kg can be cast and machined as per customer specifications. We have three VMCs having 3-Axis and 4-Axis configurations. This automation enables us to minimize rejection rate and improve productivity and makes us more competitive.

- The VMC operations are supported by dedicated CAD/CAM software like Power Shape, Power Mill, Solid Works and AutoCAD.

- Finished components can be custom painted if required with Epoxy based, PU based or NC based paints.

- The components can be coated or plated with abrasion resistant and corrosion resistant media.

- The components can be supplied with Non-Destructive Testing such as Radiography, Ultrasonic test, Liquid Penetration test and Hydrostatic/Pneumatic Pressure test as per requirement.

- We can also supply Assemblies and sub-assemblies.

Our Quality Assurance Program Has The Following Distinct Features In Full Compliance With ISO 9001 QMS (Latest Version)

- 1Process Parameters are documented and Operator Training is monitored.

- One Hundred Percent (100%) Visual inspection is performed by our trained machine operators to check critical dimensions and parameters set by the customer.

- Parts are then randomly audited once again by QA personnel at the machine once every hour and rejections are logged.

- Finally, the acceptable parts are boxed, counted, and moved to the pre-shipment quality control department, where they are randomly inspected once again and the count is verified. The parts are then ready for shipment.

- Records are maintained as per ISO 9001 QMS.

- Machine maintenance is done as per formal Preventative Maintenance Program.

Facility Photos

Exterior

Interior

Favretto Torino, Italian Make Hydro Copier Planing Machine

Jyoti, India made VMC with 4-Axis configuration

Products

Component Pattern for C I Casting weighing 1100 Kg

Component Pattern for S G Iron Casting of 500 Kg

Aluminum

Pattern for C I Casting

Pattern for C I Casting

Aluminum

Pattern for C I Casting

Pattern for C I Casting

Don’t forget, we offer guarantee of zero defects quality and 97% on-time delivery performance at competitive pricing.